9000 Cavities

Annual mold production capacity

2000 Sets

Total number of delivered mold sets

200 Sets

Total number of delivered stacked molds

96+96

Maximum cavities for stack molds

48+48+48+48

Maximum cavities for cube molds

COMPANY PROFILE

Company Profile

Suzhou Unistar Mold Technology Co., Ltd. was established in 2013 with a total investment of over 70 million US dollars. It is a high-tech enterprise focused on the design, development, and manufacturing of molds for medical products, food packaging, and cosmetics packaging. We are committed to producing high-precision, multi-cavities, short cycle time, and long-life high-quality molds, providing customers with a full-process, one-stop service from design and development to manufacturing and after-sales support.

Company Background

Unistar has assembled a technical and project management team with backgrounds in globally renowned foreign enterprises, integrating advanced European and American mold design concepts and machining technologies. By combining the localized advantages of rapid response, flexible customization, and comprehensive services, we provide high-quality molds and tailored solutions for global clients. Currently, our business covers China, Europe, the Americas, Southeast Asia, and the Middle East, while continuously expanding into the global market.

In the future, Unistar will continue to increase investment in automation lines, lean management, and continuously improve quality and precision machines. We sincerely look forward to establishing long-term and stable cooperative relationships with our customers and working together to create a better future!

Main Mold Products

Medical Industry | Food Packaging | Cosmetic Packaging

Medical Industry

Unistar provides in-depth services to the medical field, offering precision molds to internationally renowned medical companies. Our products cover injection systems (such as syringes, COC/COP prefilled syringes, indwelling needles, and related products), drug delivery and diagnostic systems (such as powder inhalers, microfluidics, laboratory rapid diagnostic consumables, etc), we are also skilled in products like hemodialysis, artificial lungs, and respiratory masks. We strictly adhere to medical industry regulations and, with a deep understanding of medical control processes and production environments, ensure that our molds meet the most stringent requirements for ultra-high precision, stability, safety, contributing our professional expertise to safeguarding medical safety.

Food Packaging Industry

Unistar focuses on providing high-quality mold solutions for the food and beverage industry. Our product comprehensively covers precision cap molds, including water cap, beverage cap, oil cap, milk cap, and milk powder cap. We are also proficient in thin-wall packaging products, such as yogurt cup, ice cream cup, and chocolate boxes. Leveraging our deep understanding of food safety standards and advantages in high-cavity, short-cycle technology, we are committed to helping customers improve production efficiency, reduce costs, and ensure the safety and aesthetic appeal of packaging, enabling brands to stand out in the competitive market.

Cosmetic Packaging Industry

Unistar focuses on the daily chemical products and personal care industry, providing customers with precise and innovative packaging molds. Our products cover high-end cream jars, vacuum pumps, lotion pumps, as well as various complex product structures such as flip caps and two-tone caps. With an in-depth understanding of material applications and user experience, we are committed to achieving excellence in both product usability and appearance. At the same time, leveraging the advantages of high-cavity molds and short cycles, we help customers improve production efficiency, reduce manufacturing costs, enhance and maintain market competitiveness.

CORE COMPETENCIES

High-performance Mold Manufacturing Capability

Cutting-edge technology meet diversified production needs

Suzhou Unistar stands out in the industry with its outstanding manufacturing capabilities and technological innovation, focusing on providing customers with efficient and precise mold solutions. Our core manufacturing capabilities are reflected in the design and production of stack molds, cube molds (rotary molds), multi-cavities molds, and 2k molds. These technologies represent the cutting-edge level in the field of injection molds.

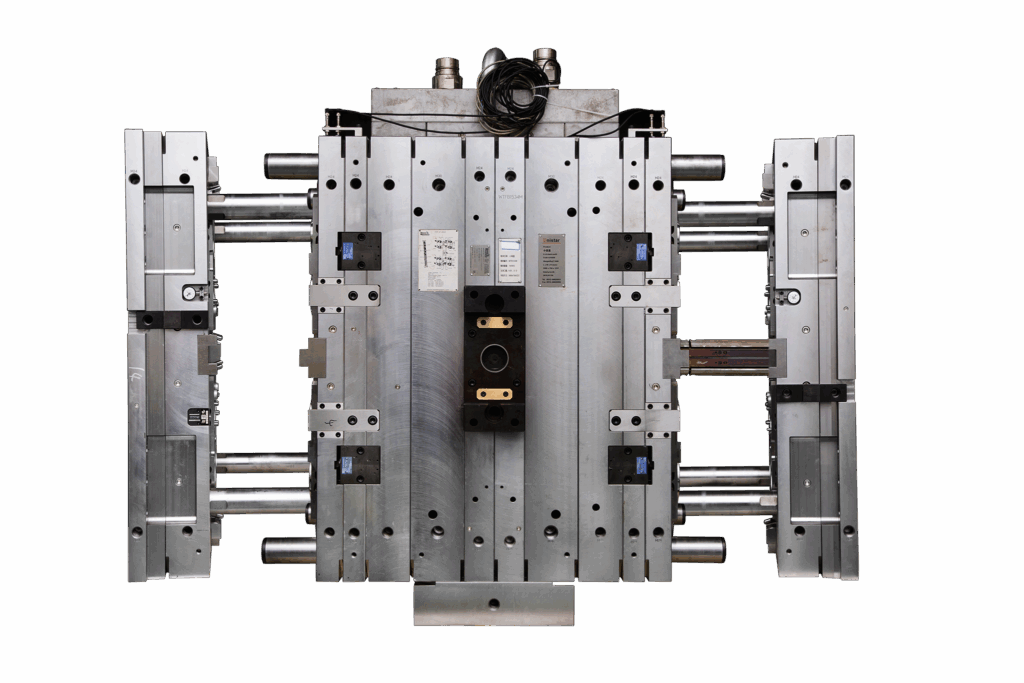

Stack Mold

In the field of stack mold technology, we possess extensive design and manufacturing experience. By applying stack mold structures, we can double the number of mold cavities on the same injection molding machine, thereby greatly increasing production capacity and significantly reducing the production cost of individual products, bringing substantial economic benefits to clients. So far, we have successfully delivered over 200 stack molds, and their mature applications now comprehensively cover industries such as medical products, food packaging, and daily cosmetics.

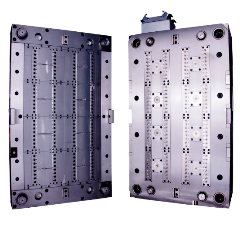

Multi-cavities Mold

Faced with the ultimate pursuit of efficiency in the medical and packaging industries, we rely on rational design to ensure the stability of multi-cavities mold and use high-precision machining to guarantee the consistency of multi-cavity mold components. We have successfully delivered ultra-multi-cavities molds with up to 192 cavities. At the same time, by optimizing materials and applying advanced processes such as 3D printing, we effectively improved cooling efficiency, significantly shortened the molding cycle. Currently, the fastest mold cycle is 2.6 seconds (including robot and in-mold labeling), helping customers gain a competitive edge in the market.

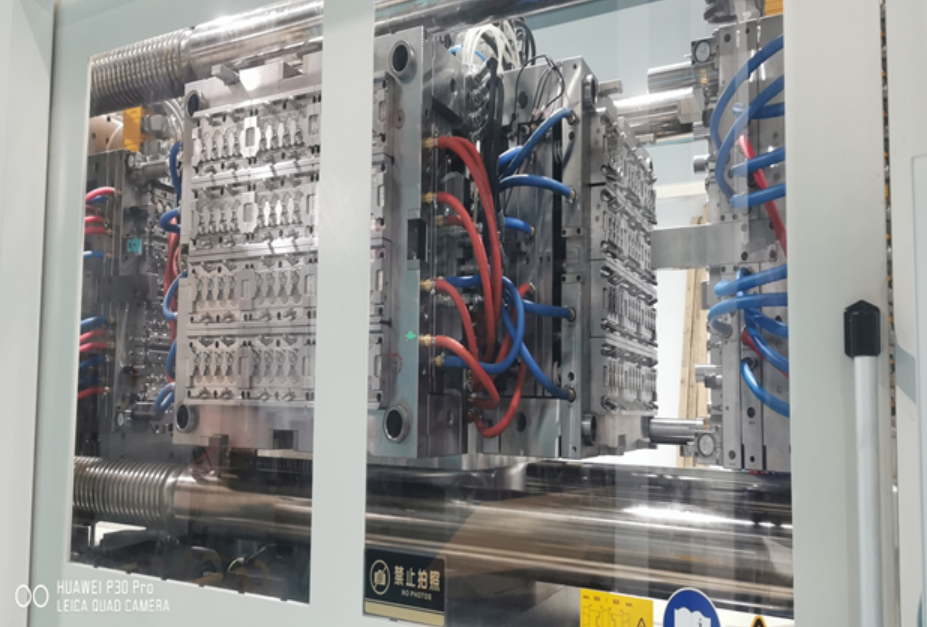

Cube Mold (Rotating Mold)

As a leader in high-cavity mold technology innovation, we collaborated with well-known injection molding machine manufacturers over three years and successfully launched the first multi-cavity cube mold in 2021. This system has been operated stably for over 10 million cycles, demonstrating outstanding reliability through various technical validations.We never stopp moving forward. Based on continuous optimization of mold stability and customer investment, we successfully developed the new generation E-cube system. It not only further enhances stability and lowers the investment threshold, but also expands the application of advanced processes such as two-color molds and in-mold assembly, providing customers with more cost-effective production solutions.

2K and Multi-color Mold

In response to the growing market demand for two-color and multi-color molds, Unistar continues to increase its R&D investment in the performance of plastic materials and mold structures, launched a variety of mature and stable mold solutions, covering advanced systems such as Cube, E-cube, Core-back, Index, and Turntable.

We are not only experienced in two-color injection molding technology, but also dedicated to optimizing molding cycles and production efficiency, helping our customers achieve product appearance and functional upgrades while effectively controlling overall production costs, providing more competitive solutions.

Major Customer

Choice of Various Well-known Customers

Always Professional, Trustworthy

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)